Comprehensive maintenance services for optimal performance & reliability:

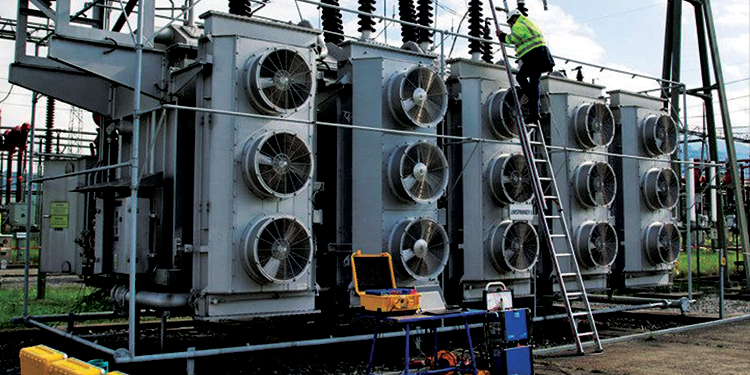

Transformer Oil Dehydration & Filtration

- Removal of moisture, dissolved gases & impurities.

- Restoration of insulation properties.

- Enhancing the lifespan of transformers.

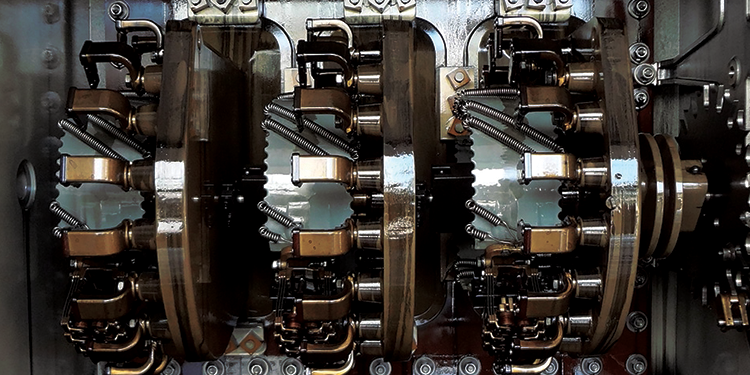

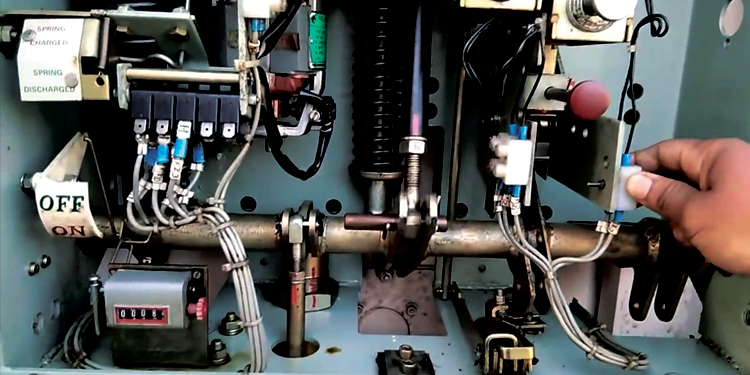

HT VCB Panel Service Work

- Inspection, maintenance & servicing of VCB panels.

- Cleaning & lubrication of moving parts.

- Contact resistance testing & recalibration.

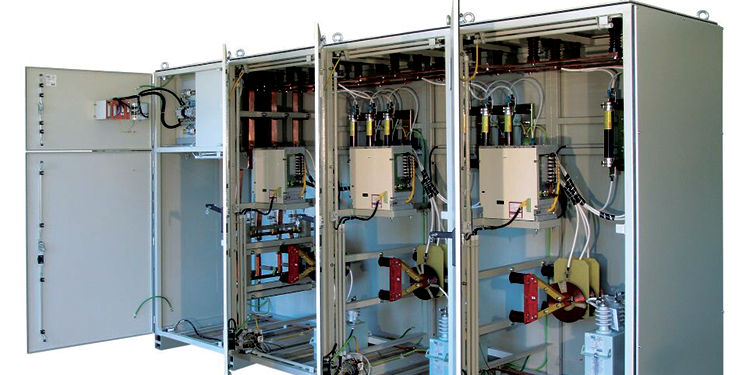

Substation & Switchgear AMC

- Preventive maintenance of transformers, panels & switchgear.

- Regular inspection & testing.

- Replacement of worn-out parts.

Protection & Control AMC

- Relay testing & calibration.

- Control system diagnostics & troubleshooting.

Cable & Termination AMC

- Cable insulation testing.

- Cable joint inspections & repairs.

- Termination tightening & verification.